News

Collaboration within this area: A soft chemical micropump actuated by self-oscillating polymer gel

●Research Team

PI Yo Tanaka(RIKEN)

Co-PI Shingo Maeda(Shibaura Institute of Technology)

A collaborative research group of Dr. Yo Tanaka (Group B01, RIKEN) and Prof. Maeda (Group A03, Shibaura Institute of Technology) has developed a self-driven chemical micropump powered by self-oscillating motions of synthetic polymer gel converting chemical energy into displacements of a thin polydimethylsiloxane (PDMS) sheet to produce a directional flow via micro check valves.

A small, clean and autonomously actuated device is an ideal machine. But conventional micromachining has a limitation of integration due to the use of external power source and controllers. On the other hand, Tanaka et al. have developed life-machine fusion devices. They work with just chemical energy input and autonomously drive. Such characteristics is unique. Cardiomyocyte pumps and earthworm muscle-based pumps/valves are representative devices. The feature of the principle of such devices is distinctive, however, it requires time to solve the endurance and ethical issues. Development of devices using artificial materials advanced from such life-machine fusion devices is necessary. Here, a self-oscillating polymer gel was used. Periodical expanding and shrinking oscillation of this polymer gel is induced by a chemical reaction called Belousov-Zhabotinsky (BZ) reaction. By using this gel instead of cardiomyocytes, an autonomously actuated micropump can be created.

A small, clean and autonomously actuated device is an ideal machine. But conventional micromachining has a limitation of integration due to the use of external power source and controllers. On the other hand, Tanaka et al. have developed life-machine fusion devices. They work with just chemical energy input and autonomously drive. Such characteristics is unique. Cardiomyocyte pumps and earthworm muscle-based pumps/valves are representative devices. The feature of the principle of such devices is distinctive, however, it requires time to solve the endurance and ethical issues. Development of devices using artificial materials advanced from such life-machine fusion devices is necessary. Here, a self-oscillating polymer gel was used. Periodical expanding and shrinking oscillation of this polymer gel is induced by a chemical reaction called Belousov-Zhabotinsky (BZ) reaction. By using this gel instead of cardiomyocytes, an autonomously actuated micropump can be created.

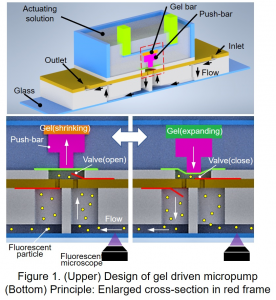

The pump design and principle are shown in Figure 1. The repetitive expanding and shrinking motions of the polymer gel bars are transferred to fluids in a microchannel via a PDMS push-bar and a thin membrane and generate a periodical driven flow by check valves without any on-off switching. Direct pushing force of gel bars is used because a large space is required, and the integration is difficult if pulling force of the gel bar is used.

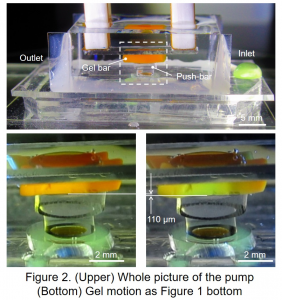

Before the observation in a microchannel to confirm pump function, it was confirmed that the gel bars were actually pushing the push-bar as illustrated in Figure 1 (bottom). Figure 2 is the actual images measuring the PDMS push-bar displacement. The displacement was measured by close-setting camera around the gel bars between a fixed glass substrate and push-bar. The displacement was about 110 μm and the corresponding fore was calculated about 0.07 mN.

Before the observation in a microchannel to confirm pump function, it was confirmed that the gel bars were actually pushing the push-bar as illustrated in Figure 1 (bottom). Figure 2 is the actual images measuring the PDMS push-bar displacement. The displacement was measured by close-setting camera around the gel bars between a fixed glass substrate and push-bar. The displacement was about 110 μm and the corresponding fore was calculated about 0.07 mN.

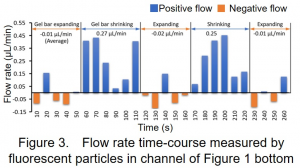

The periodical flow was observed visualized with microbeads under fluorescent microscopy as shown in Figure 1 (bottom) at 25°C. Check valves were fabricated by covering the penetrate hole under the chamber with a thin PDMS membrane (10 μm thickness). The result is shown in Figure 3. In each periodic cycle, positive flow rates were relatively larger than the negative flow rates. The micropump produced an average (net) positive flow rate of 0.28 µL/min. This is enough as a micropump.

After the micropump function was verified, the temperature effect on the micropump performance was investigated. The flow rate increased along with the increment of temperature. Together with this thermal sensitivity, a self-controlled drug delivery system can be one example of applications.

After the micropump function was verified, the temperature effect on the micropump performance was investigated. The flow rate increased along with the increment of temperature. Together with this thermal sensitivity, a self-controlled drug delivery system can be one example of applications.

Compared to existing chemical micropumps, this gel-based micropump provides advantages of self-oscillating property, easy refueling and thermal controllability. This gel-based soft micropump would be used as wearable or medical devices exploiting the flexibility and quietness. Another significance of this study was to show the advanced version of muscle cell based microactuators which also actuate using chemical energy in the medium. Differently from such living system dependent devices, this gel-based system does not use living cells or tissue but use a bio-mimetic material. This characteristic is useful for control and long-term use of the device. Such replacement would be one of the evolutions of life-machine fusion devices.

The study was published in “Sensors and Actuators B: Chemical” by Elsevier.

Paper title: A chemical micropump actuated by self-oscillating polymer gel

Link to the paper: https://doi.org/10.1016/j.snb.2021.129769